As industries continue to evolve and become more technologically advanced, so do flow meters. The latest advancements in flow meter technology have brought about increased accuracy, better reliability, and enhanced data integration. Some modern flow meters come equipped with digital interfaces that allow for real-time data monitoring and remote control. This level of connectivity is invaluable in industries where quick decision-making and immediate responses to fluctuations in flow rates are critical.

Industry-Specific Applications of Flow Meters

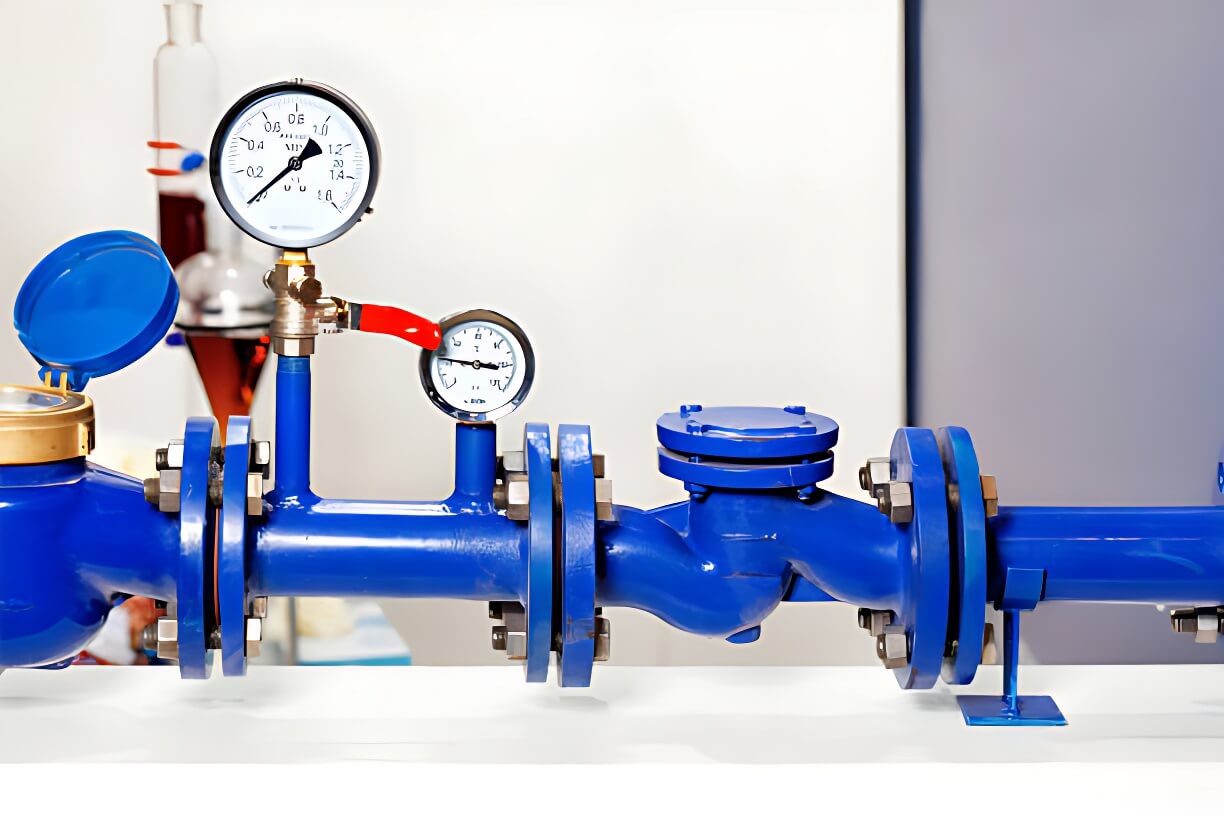

Flow meters find their applications in a multitude of industries, each with its unique requirements:

- Oil and Gas: In the oil and gas sector, flow meters are utilized at various stages, from measuring the flow of crude oil during extraction to monitoring the distribution of refined products. The ability to accurately quantify the flow of these valuable resources is essential for operational efficiency and revenue management.

- Pharmaceuticals: The pharmaceutical industry relies on precise flow measurement to ensure the accurate mixing of ingredients in drug manufacturing. Additionally, flow meters play a role in regulating the flow of gases used in pharmaceutical processes.

- Water Management: Flow meters play a pivotal role in water management systems. They are used to measure the flow of water in distribution networks, wastewater treatment plants, and irrigation systems, aiding in efficient resource allocation.

- Food and Beverage: From controlling the flow of ingredients in food processing to monitoring the filling of beverage containers, flow meters are essential in maintaining product consistency and meeting quality standards.

- Chemical Processing: The chemical industry utilizes flow meters to measure the flow of various chemicals with different viscosities and properties. Accurate flow measurement ensures precise mixing and prevents chemical reactions from going awry.

Factors Influencing Flow Meter Accuracy

Accurate flow measurement is the cornerstone of reliable data and process control. Factors that can influence the accuracy of flow meters include fluid properties, installation conditions, and calibration intervals. A knowledgeable flow meter supplier like ControlTech ME can provide guidance on selecting the right meter for your specific application to ensure optimal accuracy.

Future Trends in Flow Metering

As technology continues to advance, several trends are emerging in the field of flow metering:

- IoT Integration: The Internet of Things (IoT) is revolutionizing industries by enabling devices to communicate and share data. Flow meters equipped with IoT capabilities can transmit real-time data to centralized systems for monitoring and analysis.

- Wireless Connectivity: Wireless communication technologies are becoming more prevalent in flow meters. This eliminates the need for extensive wiring during installation and allows for easier integration into existing systems.

- Energy Efficiency: New flow meters are designed to be more energy-efficient, consuming less power while maintaining accuracy. This not only reduces operational costs but also contributes to sustainability efforts.

- Data Analytics: The data collected by flow meters can be harnessed for predictive maintenance and process optimization through data analytics. This can lead to reduced downtime and improved overall efficiency.

Conclusion

In the dynamic landscape of industrial processes, flow meters are the unsung heroes that ensure operations run smoothly, efficiently, and accurately. From selecting the right type of flow meter based on fluid properties to choosing a reputable supplier like ControlTech ME, every step in the process matters. The advancements in flow meter innovative technology are transforming industries and enabling data-driven decision-making like never before. As industries in the UAE and around the world continue to grow, the role of flow meters will only become more vital in ensuring precision, efficiency, and success.